The Freightliner SuperTruck II: Behind the Design

Freightliner Fuel Efficiency

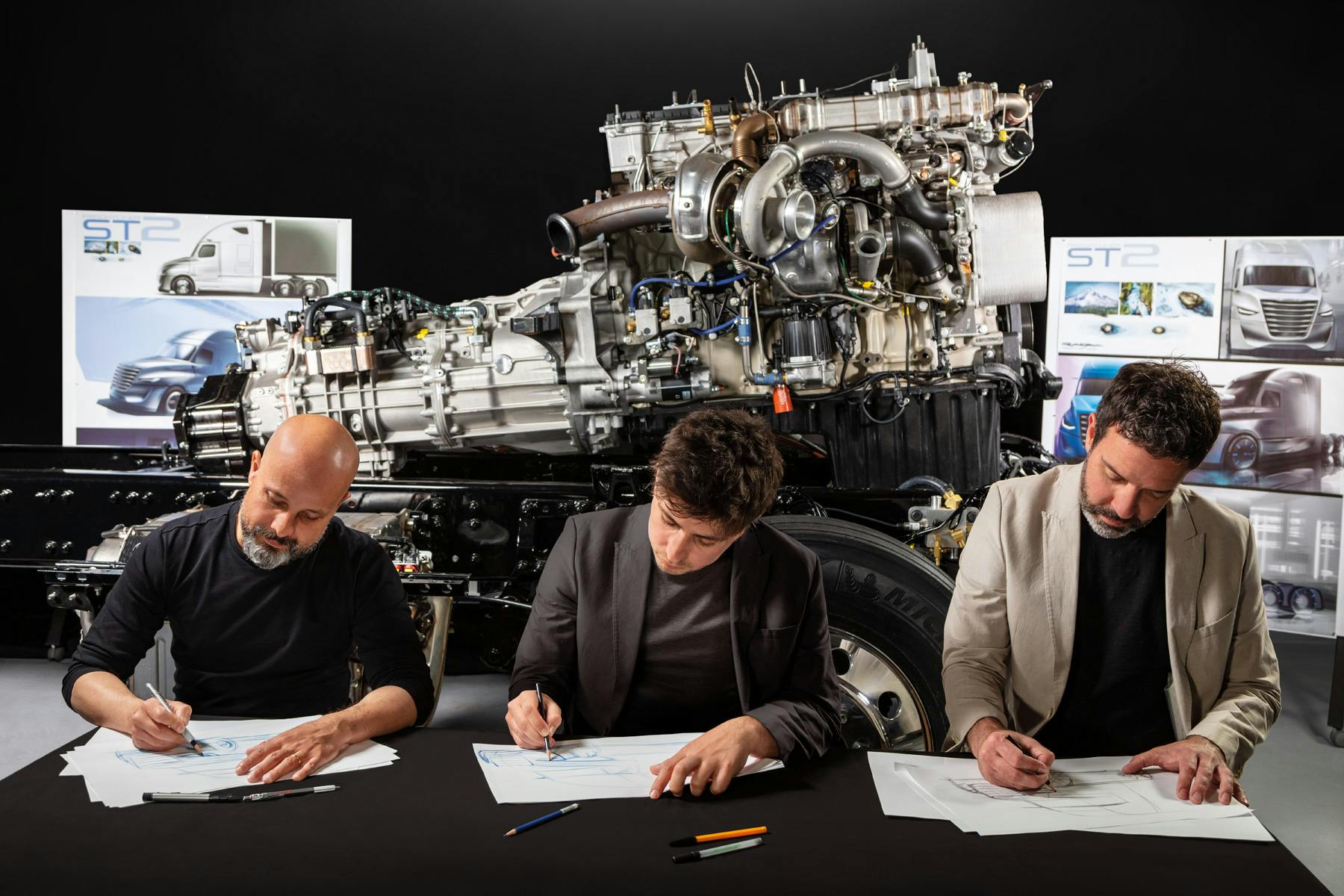

Jeff Cotner, chief designer and design development manager at Daimler Truck North America (DTNA), leads the creative team for Freightliner and Western Star. He was joined by senior designer Mauricio Cavalheiro and Rafael Dos Santos, senior interior/exterior designer. Together, with the advanced engineering team, these designers worked to bring to life SuperTruck II, a vehicle that pushes the boundaries of what is possible in the transportation industry.

HISTORY OF THE SUPERTRUCK

The SuperTruck program was launched by the U.S. Department of Energy (DOE) in 2009 to improve the fuel efficiency of heavy-duty trucks by 50%. To achieve this goal, the program encouraged original equipment manufacturers (OEMs) to develop innovative technologies, materials and designs that could be applied to long-haul trucks through a funding initiative.

Freightliner’s SuperTruck I was unveiled in 2015 and featured a number of advanced technologies, including an Integrated Detroit® Powertrain™, the ability to downspeed the engine, an innovative grill design and aerodynamic improvements to the tractor-trailer. SuperTruck I achieved a 115% improvement in freight efficiency over the 2009 baseline vehicle, more than doubling the DOE’s goal.

Building on the success of SuperTruck I, Freightliner took on a new SuperTruck challenge from the DOE: to develop a semi truck solution that could double the freight efficiency from the first SuperTruck while using technologies that could potentially be commercialized today. This challenge resulted in Freightliner’s SuperTruck II, which was unveiled earlier in 2023.

INITIAL INSPIRATION

During the development of SuperTruck II, the advanced engineering team worked closely with the design team to ensure that the truck’s aesthetics matched its performance. Collaboration between the different teams was essential to achieve the best of both worlds – a visually appealing yet aerodynamically efficient semi truck.

The team drew inspiration from nature and the idea of wind sculpting the vehicle to create a new form language and identity for the Freightliner brand.

They started with loose sketches and clay modeling sculptures, discussing the meaning of the shapes and volumes and how they could be optimized for aerodynamic performance, ultimately creating a smooth, sculpted design with precision graphics. As a result of the collaboration between teams, the final design achieved the advanced engineering team’s fuel efficiency targets.

AESTHETICS VS. FUNCTIONALITY

As a designer, balancing aesthetics and functionality is always a challenge.

“We had to make some corners of the truck much softer than we had originally planned to avoid vortexes and other aerodynamic issues,” said Cavalheiro. “We also worked extensively on the lines and shapes around the fender to optimize its performance.”

Other planned designs were scrapped entirely after consulting with the aerodynamics team. “We had the intention to make an intake duct in the bumper, but it turned out to be an advantage for the aerodynamic performance to avoid having low pressure inside of the wheel arches.”

After several iterations, they achieved the desired curvature, which was crucial for the overall design. Additionally, the team dedicated significant effort to refining the back of the hood. They focused on managing the airflow as it leaves the hood and interacts with the windshield, striving to maintain a compressed and attached flow for optimal aerodynamics.

AN EVOLUTION OF THE FREIGHTLINER BRAND

Freightliner has a long-standing history of creating efficient business solutions, with designs that prioritize fleet needs and bottom lines. With SuperTruck II, the team continued this trajectory by emphasizing efficiency and seamless integration, resulting in a truck that is sleek and modern. In line with the rest of the Freightliner product lineup – purposeful, straightforward and sensible – SuperTruck II exemplifies Freightliner’s commitment to providing customers with high-performance, cost-effective solutions.

“While there’s a history of taking risks in the company, the difference with the SuperTruck II was the total effort that went into creating it,” said Dos Santos. “Every team was pushing the truck to its absolute 100% to achieve the best possible product. The joint effort between engineering, the aero group, advanced engineering and the design center resulted in the most unique vehicle the company has ever made.”

SPOTLIGHTING FAVORITE FEATURES

Each member of the design team has a distinct favorite feature of the final SuperTruck II design.

Dos Santos highlights the air intakes on the bumper, which are the largest on any Freightliner truck and create a Venturi effect. This phenomenon describes when the speed of air increases as it flows through a narrower passage. As air enters through the large intakes on the bumper, it is forced through a narrower space, causing the air to accelerate and move faster around the vehicle, improving its aerodynamics.

For Cavalheiro, it’s the headlamps following the shape of the fender. “Not like angry eyes, just calm and focused,” he explained.

Cotner points out that getting rid of the mirror and incorporating the air intake and body contour in the area between the hood and the door creates a holistic and beautiful form.

SUSTAINABLE DESIGN

SuperTruck II is not an electric semi truck, though it pushes the boundaries of Freightliner’s vision for sustainable design by optimizing current technologies.

“The range of an electric truck is not there yet for heavy hauling,” said Cotner. “This advanced truck could actually be produced in the near future, and drivers could take it on the road today and it’ll do everything that’s promised.”

The design team worked to optimize each component of the vehicle with efficiency (and sustainability) in mind, including steering, combustion, transmission and systems that bridge the gap between the trailer and the truck itself. They focused heavily on aerodynamics, spending countless hours in the wind tunnel to squeeze out every last count of air resistance.

“The longevity of the design and the life cycle of the product should also be considered as part of its footprint,” adds Cavalheiro. “By delivering a timeless design, customers will desire the product for a longer period, reducing the need to replace it with new designs that quickly become outdated. This is part of our team’s commitment to sustainability.”

INFLUENCES ON FUTURE PRODUCT DESIGN

The design process involves creating many ideas, but not all of them can make the final cut. However, those ideas can still be used for future projects.

“Most ideas will die,” said Dos Santos. “For every one design you see on the truck, hundreds of designs are dead behind it. Sometimes an idea sounds great, but it’s too expensive for customers and not realistic at the moment. Our goal was to create a vehicle that not only pushes the boundaries of design but also meets the needs of our customers today.”

The most significant learning from the SuperTruck II project is the importance of collaboration from the beginning between design and engineering departments to achieve incredible results, ensuring an end product that was both innovative and practical.

“This collaboration requires mutual respect and finding a balance between each discipline’s objectives,” said Cotner. Going forward, the team hopes to continue this collaborative approach, and they also aim to explore new design features such as a door that is flush with the sleeper side to further improve aerodynamic performance.

PATH TO SUPERTRUCK III

With the launch of SuperTruck II behind them, SuperTruck III is already on the horizon. Having already been awarded funding by the DOE for the next stage in the program, Daimler Truck North America is still in the early phases of discussing the vehicle’s overall design. This time, however, they’re focusing more on zero-emission propulsion and the possibilities of hydrogen fuel cell technology.

The team emphasized that Freightliner’s commitment to customer-focused efficiency and peak performance will still be a top priority for SuperTruck III. The design language will continue to focus on further improving efficiency and total cost of the vehicle.

“SuperTruck III will be what happens when you push the ideas from SuperTruck II even further,” said Dos Santos.

As we embark on the journey to SuperTruck III, our team at Freightliner remains dedicated to creating innovative and high-performance trucks. We will continue to push the boundaries of what is possible in the transportation industry, ensuring that our customers receive the best products and services possible. The lessons learned from the SuperTruck II project will undoubtedly guide our future endeavors, helping us to shape the future of trucking with a strong focus on efficiency, safety and sustainability.